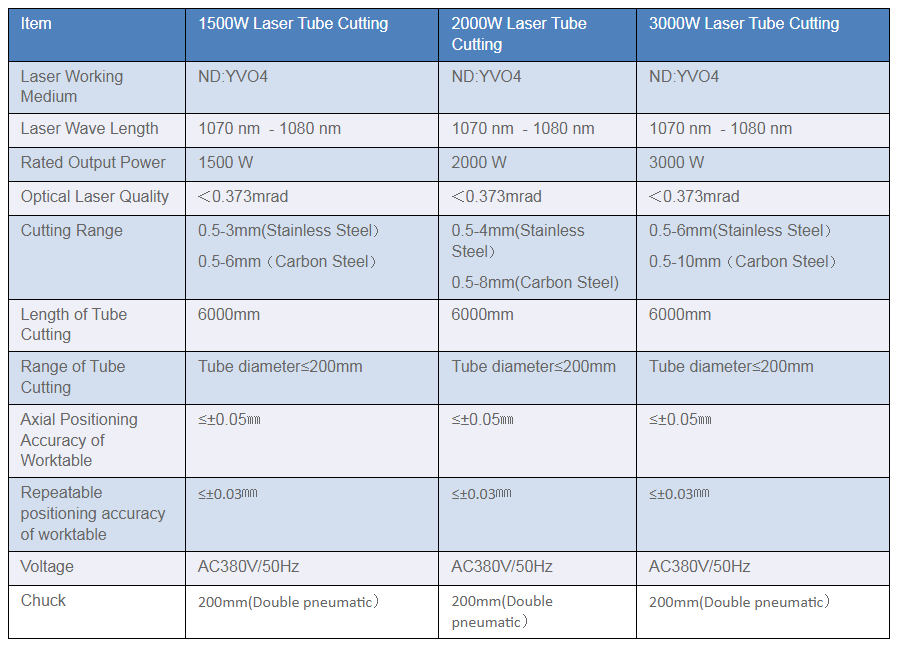

1. Regarding stabilizing electric transformer, for 220V 60hz e phase, how many KVA is required?

The transformer capacity is depends on the laser power. For laser power 1000W, it requires 40KVA.

2. PLC, has English or maybe Spanish language?

Our touch screen has both English and Chinese language. We can add Spanish or other language with your help for the translation.

3. Can we send you sample of our pipe in order for you to show us cutting of our material?

Yes, we always welcome customer send us their pipe for testing. Kindly send us pipe length ≥600mm, qty ≥ 3pcs for each size. The longer size and the more quantity the better.

4. What is the material loss every time laser cuts? I mean, when laser is cutting what is the length waste for every cut?

The laser cutting loss is very small, only 0.05-0.1mm/cut, while saw cutting loss would be about 2-5mm/cut.

5. After laser cuts, is the edge hardened by the laser temperature? Can we flare pipe easily without problem after cutting?

The hardening effects are different on different pipe materials. We suggest customers send us their tubes for testing and check the result.

6. Under what circumstances should I choose to use a laser machine?

If cutting quantity is more than thousand pieces per day, we suggest laser machine. As it has advantage on the cutting loss, operation cost(0.6USD/hour) and high efficiency(fast and no burr). In long term usage, laser machine can bring you more profits.

7. When can it cover the machine cost and gain profits for me?

According to our surveys, usually it would take about 0.5 to 1.5 years for our customers to cover the machine cost by the profits they obtained on the laser machine.