With the development of laser cleaning technology and equipment, it is more and more widely used in various industries. At present, most of the hardware products still be used by traditional cleaning methods in the processing of production. there are various defects, and it’s an extensive and high energy consumption operation method

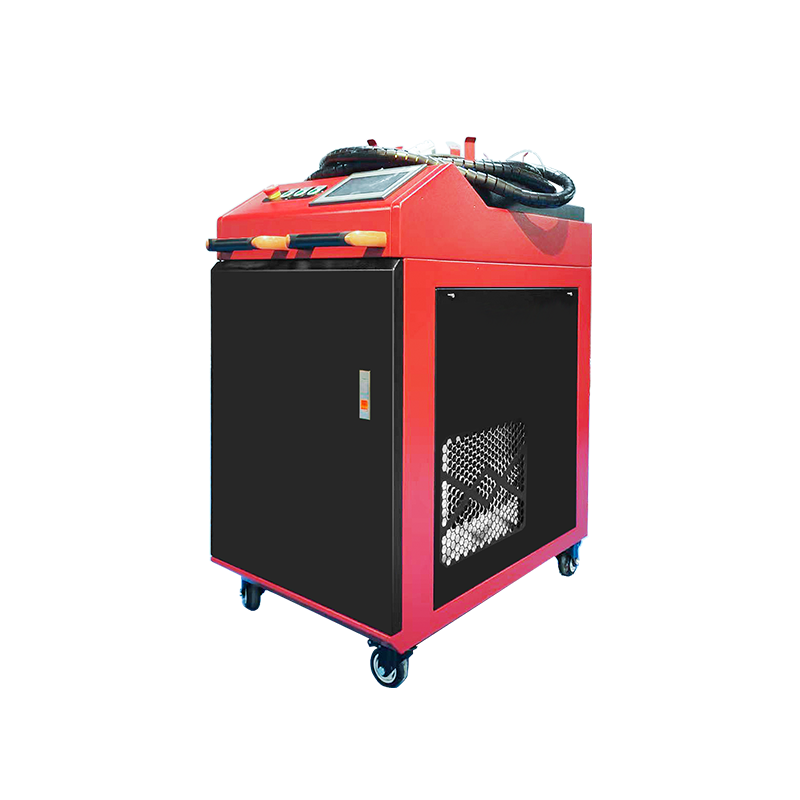

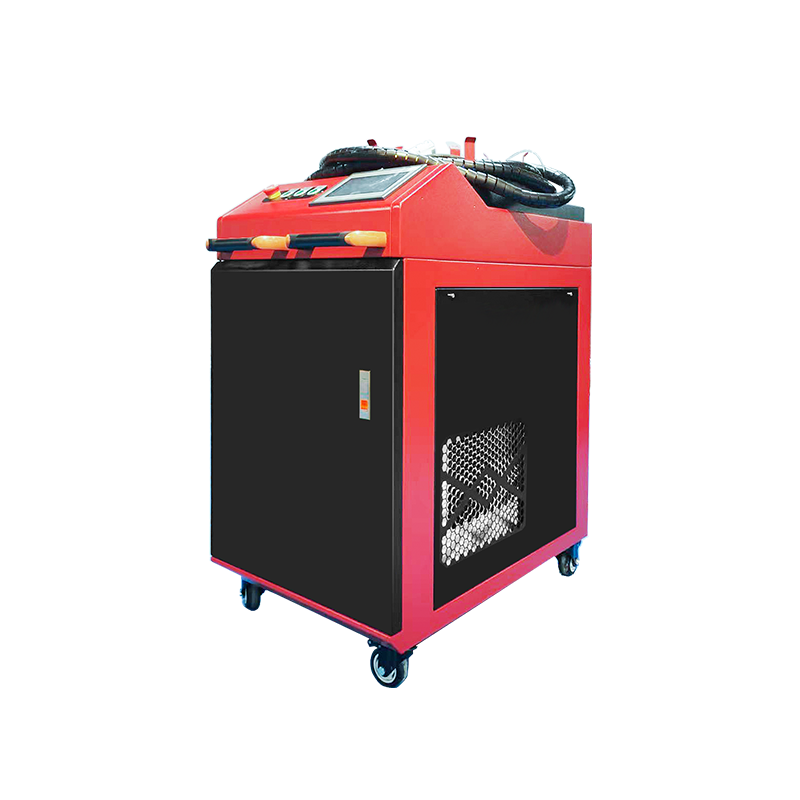

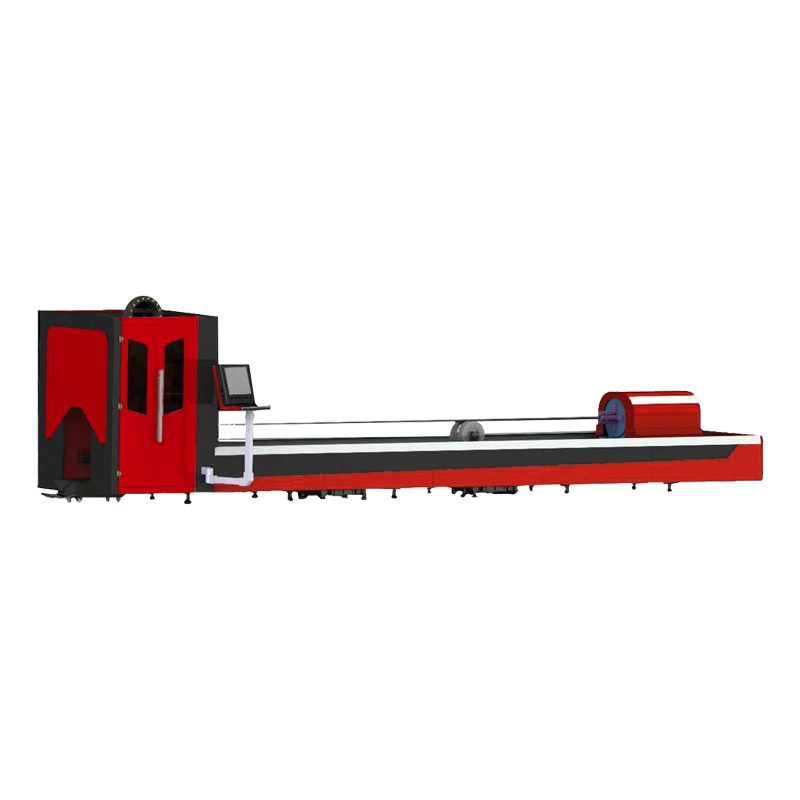

Continuous optical fiber laser cleaning machine is PRATO introduced in the application of metal, building materials, crafts and other metal processing equipment. Compact equipment, easy to move and handle, flexible and convenient operation. It can realize outdoor welding, and suitable for a variety of complex metal hardware

Fast welding efficiency

1.Characteristics of the Equipment

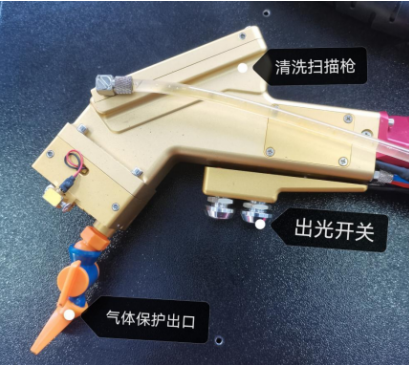

Handheld cleaning operation mode, can realize any part of any Angle of the workpiece cleaning;

Ergonomic design, small size light weight, flexible and convenient operation;

Choiceness washing mouth material to avoid scratching the surface of the workpiece;

Optional washing mouth , easily realize the welding operation of different products;

Equipped with safety loop, avoid the wrong light, the operation is safer

Hand-held cleaning head can choose switch button for light, and it also can also use foot to trigger light;

Wear protective glasses when cleaning.

Laser cleaning machine can clean rust, oxide skin, paint layer and oil.

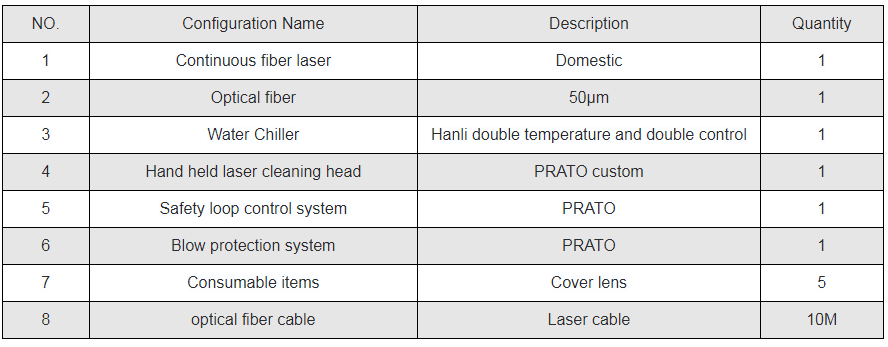

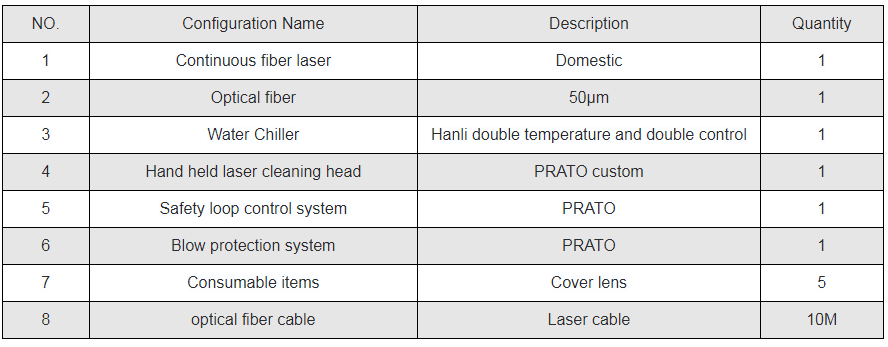

2.The Main System Configurations

3.Continuous Fiber Laser

PLT-QX15 laser features

Continuous mode light output;

Lower maintenance cost, lower power - 0 consumables;

Maintenance free; The electro-optical conversion efficiency is about 25%.

Ideal beam quality -- beam quality BPP= (3.4-5.4);

The whole machine is equipped with a water chiller to realize the constant temperature environment of the laser, which can greatly reduce the risk of condensation in the inner part of the laser;

Extremely high stability and long pump life -- over 100,000 hours pump source life.

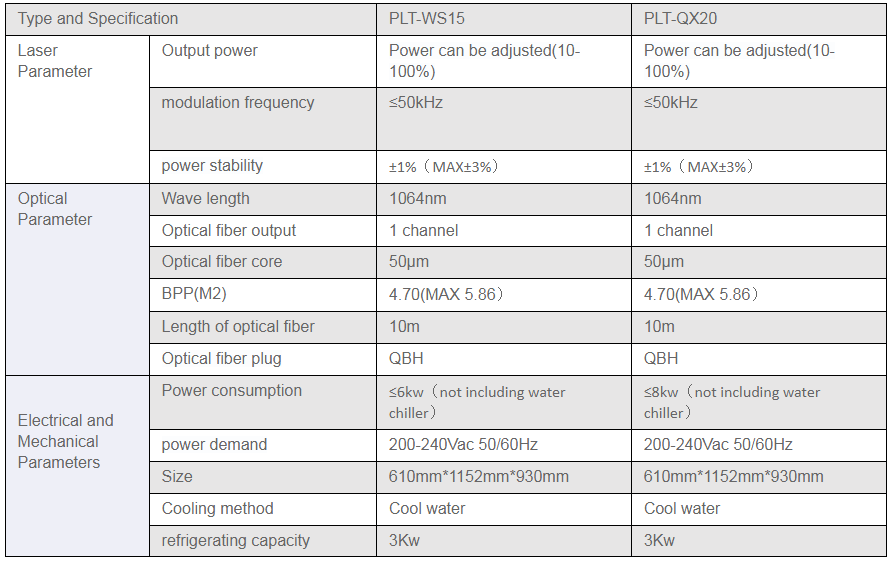

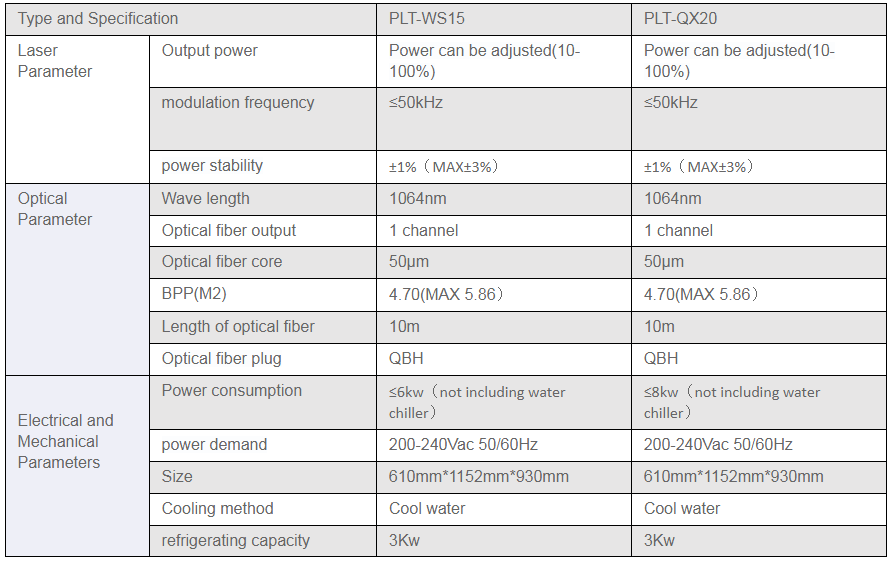

Continuous fiber Laser Specification

4.Characteristics of Water Chiller

A variety of temperature control accuracy selection, to meet different needs, optional temperature control accuracy of ±0.1℃, ±1℃ and ±2.5℃;

Double temperature and double circulation system, each channel temperature can be controlled separately (the secondary channel temperature should be set higher than the main channel);

with level alarm, phase sequence alarm, pressure alarm and component failure alarm;

Stainless steel water pump, PE water tank, water circulation system does not contain copper, aluminum, iron and other metals, completely not rust;

5.Hand Held Laser Cleaning Head

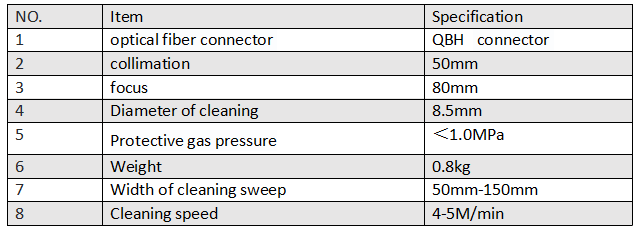

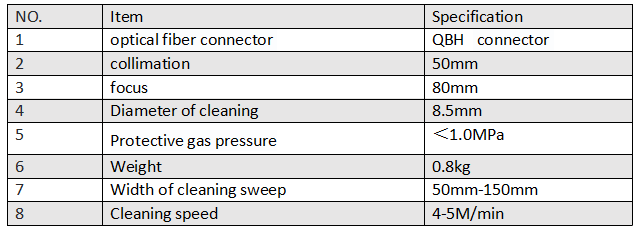

Specification of hand-held laser cleaning head